SYNC 2

Reliability, Flexibility and Affordability Fused with Modern Shrinkwrapping Conveniences

Engineered for maximum flexibility, reliability and performance. Conflex® shrink packaging equipment incorporates leading-edge technology to take on the toughest shrink packaging challenges.

Value Priced – Versatile and Flexible

The Conflex® SYNC 2 second generation continues its reputation as the shrink wrapping industry’s best value! The combination of high speed servo motion, modern easy to use controls and time tested machine design make the SYNC 2 the perfect shrink wrapper for automatic applications. Conflex® makes the SYNC 2 the smart choice for shrink wrapping solutions.

Standard Features

- Continuous Motion Cross Seal – Servo and FAST!

- operator-friendly product setups in three languages

- Easy Load Film Cradle – The fast threading process makes changeovers more efficient

- Self-Tracking Belts – Eliminates tracking issues and reduces maintenance (infeed & transfer only)

- Open Access/Swing-Out Inverting Head – Allows fast film threading

- Mushroom Style Cross Seal – Provides positive hot knife sealing on most films

- UL Listed Electronics – For dependable operation

- Casters and Leg Levelers – Standard equipment

- 4 Modes of operation – provides a variety of product spacing opportunities

- Multiple Options Available – Left-to-right product flow, stainless steel and other customizable options available

- Allen Bradley Electronics

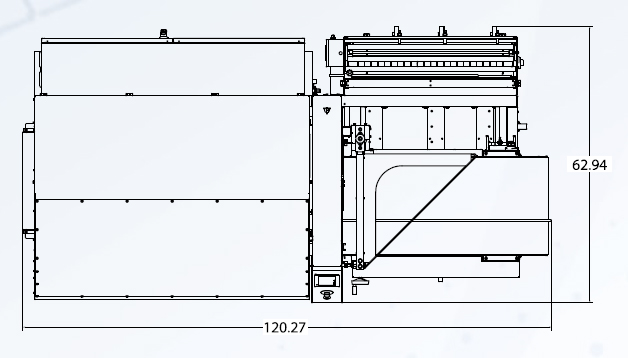

Specifications

| Electrical Requirements | 220V, 20 Amps, 3 Phase |

| Air Requirements | 80 psi, 3 cfm |

| Seal Bar Width and Height | 24” wide, 10” high |

| Maximum Film Width | 30”* |

| Maximum Roll Diameter | 14” |

| Overall Machine Dimensions | 120” L x 57.5” W x 59.5” H |

| Maximum Operating Speeds | 100’ film per minute** |

| Deck Height on Casters | 34.75” |

| Package Dimensions* | 3” L to unlimited L 1” W to 22” W** 1/8” H to 10” H |

*May require additional components and set-up time to run the entire size range

** Product dependent