SmartFlight

Conflex® … Flexible People make Flexible Systems

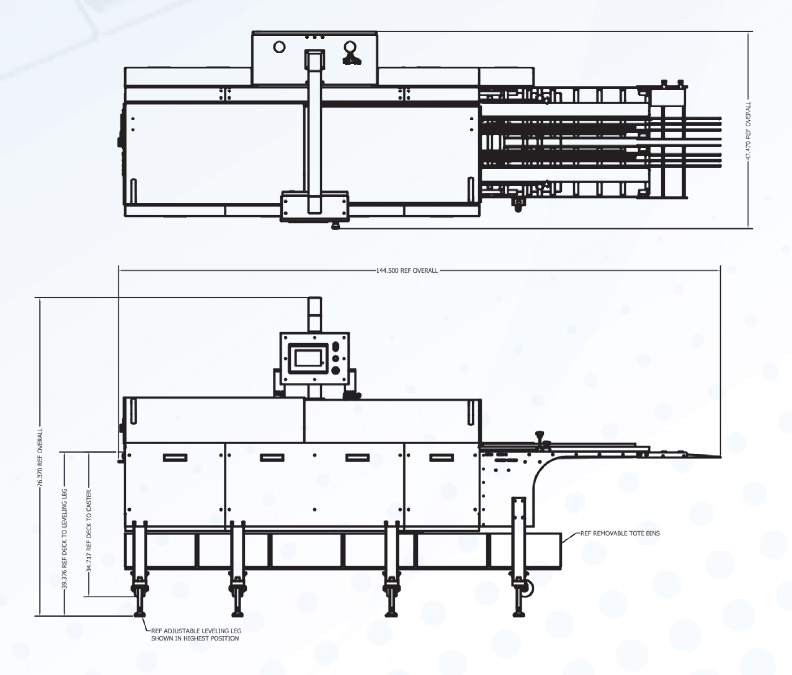

Engineered for maximum capacity, flexibility, reliability and performance. Conflex Inc. is committed to developing products that provide solutions to the packaging industries toughest challenges. The SmartFlight is no exception, by providing an indexing and spacing system that has the benefits of positive flighted product placement while indexing into downstream targets at high speeds.

Standard Features

Unique Features of the SmartFlight

- Integrates into existing line and machinery

- Precise servo driven product placement and indexing

- Stainless version is washdown capable with Nema 4X enclosure

- Capable of controlling downstream equipment to match incoming rate

- Recipe based controls for accurate repeatability

- Full Allen Bradley electronics package

Specifications

| Electrical Requirements | 240 Volt, 8 FLA, 3 Phase |

| Air Requirements | 100 psi, 20 cfm (cabinet cooler) |

| Min. / Max Product Width | 7” Min. / 16” Max.* |

| Min. / Max Product Length | 7” Min. / 48” Max.* |

| Min. / Max Product Height | 1/4” Min. / 8” Max. (product dependent) |

| Maximum operating Speeds | 120 Products / minute** |

| Overall Machine Dimensions: | 130” L x 48” W x 72” H (on casters) |

| Gross Weight | 1,400 lbs. |

| Deck Height on Casters | 35” up to 42” on leveling pads |

**May require additional components and set-up time to run the entire size range

** Product dependent